Description

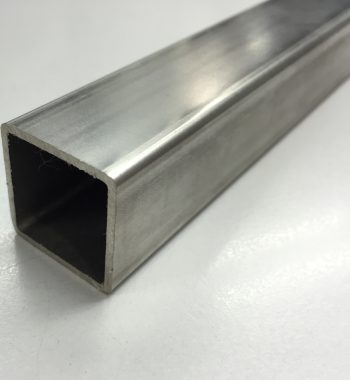

Alloy 20 Rectangular Pipes, Alloy UNS N08020 ERW Pipes, Alloy 20 Capillary Tubes, Alloy 20 EFW Tubing Leading Manufacturers.

ASTM B729 Alloy 20 Seamless Pipes, Alloy 20 ASTM B 464 Welded Tubes, Alloy 20 Square Pipes Suppliers.

DIN 2.4660 Alloy 20 Round Pipes Manufacturer, ASME SB 468 Alloy 20 Hydraulic Tubes, Alloy 20 Polished Pipes, Alloy 20 Black Round Tubes Exporter.

Even though these Carpenter 20 Pipes and Tubes were designed for use in sulfuric acid related industries, it finds an extensive usage all the way through the chemical processing industry. Meanwhile, they are excellent general corrosion resistance to sulfuric acid. As a manufacturer, supplier, stockiest andexporter, we offer these pipes and tubesin custom-made sizes and thicknesses as per the exact demands of our esteemed clients.

Alloy UNS N08020 Pipes & Tubing Equivalent Grades

| STANDARD | WERKSTOFF NR. | UNS | AFNOR | EN |

| Alloy 20 | 2.4660 | N08020 | Z2NCUD31-20AZ | NiCr20CuMo |

ASTM B 729, B464, B468 Alloy 20 Pipes & Tubes Specification

Dimensions : ASTM, ASME and API

Specifications : ASTM B 729, 464, 468 / ASME SB 729, 464, 468

Grade : Alloy 20 – UNS N08020

Size : 4 to 219mm W. T.: 0.5 to 20mm

Type : Seamless / ERW / Welded / Fabricated / LSAW Pipes

Form : Round, Rectangular, Hydraulic, Square

Length : Within 13500mm

End : Plain End, Beveled End, Treaded

Alloy 20 Pipes & Tubes Chemical Composition

| Element | Alloy 20 |

| Ni | 32 – 38 |

| Fe | Bal |

| C | 0.02 max |

| Mn | 1 – 2 |

| Si | 0.7 max |

| Cu | 3 – 4 |

| Cr | 19 – 21 |

| Mo | 2 – 3 |

| S | 0.005 max |

| P | 0.02 max |

| Nb | 0.1 – 0.3 |

Alloy 20 Pipes & Tubing Physical & Mechanical Properties

| Element | Alloy 20 |

| Density | 8.1 g/cm3 |

| Melting Point | 1443 °C (2430 °F) |

| Tensile Strength | Psi -80,000, MPa -551 |

| Yield Strength (0.2%Offset) | Psi – 35,000, MPa – 241 |

| Elongation | 30 % |