Description

Super Duplex Steel DIN 1.4410 Rectangular Welded Pipes, Super Duplex S2507 ERW Pipes, UNS S32750 EFW Tubing Leading Manufacturers.

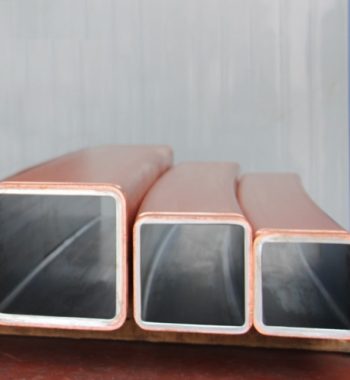

ASTM A790, A789 Super Duplex Steel Seamless Pipes, Super Duplex S32750 Welded Tubes, UNS S32760 Square Pipes Suppliers.

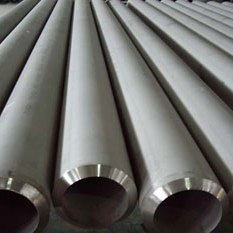

ASTM A790 Super Duplex Steel S2507 Seamless Pipes Manufacturer, ASTM A789 Super Duplex S32760 Round Pipes, UNS S32750 Polished Pipes, ASME SA 790 S2507 Pipes, Super Duplex Steel Black Round Tubes Exporter.

Super Duplex Steel UNS S32760 Pipes and Tubes are mainly used for Oil & Gas and marine applications. Meanwhile, we as well offer these pipes and tubes in customized thicknesses and sizes as per the précised requirements given by our valuable customers in international quality of standards.

Super Duplex Steel S2507 Pipes & Tubing Equivalent Grades

| STANDARD | WERKSTOFF NR. | UNS |

| Super Duplex S2507 | 1.4410 | S32750 / S32760 |

ASTM A790, A789 UNS S32750 Super Duplex Steel Pipes & Tubes Specification

Dimensions : ASTM, ASME and API

Specifications : ASTM A790 / ASME SA790, ASTM A789 / ASME SA A789

Schedule : SCH 5, SCH10, SCH 40, SCH 80, SCH 80S, SCH 160, SCH XXS, SCH XS

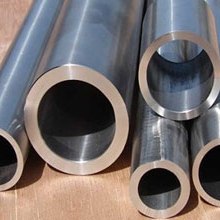

Outer Diameter : 6.00 mm OD up to 250 mm OD, Sizes up to 12” NB

Thickness : 0.3mm – 50 mm

Type : Seamless / ERW / Welded / Fabricated / CDW

Form : Round Pipes/Tubes, Square Pipes/Tubes, Rectangular Pipe/Tubes, Coiled Tubes, “U” Shape, Pan Cake Coils, Hydraulic Tubes

Length : Single Random, Double Random & Required Length

End : Plain End, Beveled End, Treaded

Super Duplex S2507 Pipes & Tubes Chemical Composition

| Element | S32750 |

| C | 0.030 |

| Si | 0.80 |

| Mn | 1.20 |

| P | 0.035 |

| S | 0.020 |

| Cr | 24.0/26.0 |

| Mo | 3.0/5.0 |

| Ni | 6.00/8.00 |

| N | 0.24/0.32 |

| Other | Cu:0.50 |

UNS S32750 / S32760 Pipes & Tubing Mechanical Properties

| Element | 2507 |

| Tensile Strength(MPa) | 795 |

| Proof Stress 0.2% (MPa) | 550 |

| Elongation A5(%) | 15 |

| Hardness Max (HB-HRB) | 310-32* |

Reviews

There are no reviews yet.